Radiators for..

Power Transformers.

Distribution Transformers.

0

Vast Reputation

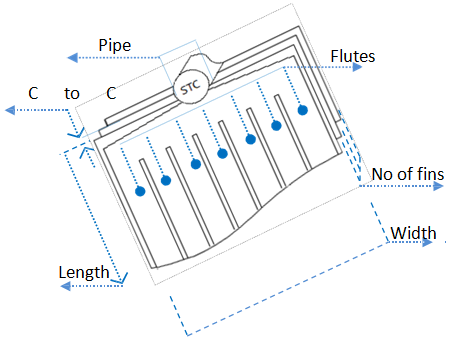

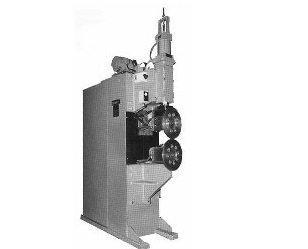

STC Radiators, established in 1993 and was formed to provide Pressed type steel Radiators for electric distribution Transformers.

0

Happy Customers

Since many years we share a strong business relation with more than 200 customers across transformer manufacturing industry.

0

Radiators Sold

We have sucessfully sold more than 150000 radiators so far and still counting on...